|

|

|

Alloy Design and Development Laboratory

|

|

Alloys for high temperature utilization (e.g., superalloys) and light-weight structures (e.g., Mg alloys) are designed and developed in this laboratory. Commercially available software is used in alloy design. Alloy production in poly and/or single crystalline forms usually follows the design stage.

Supervisor: Ercan Balıkçı, Location: KB226

|

|

Alternative Fuels and Combustion Technology

Laboratory

|

|

The function of this laboratory is to have an environment to test performance and combustion characteristics of internal combustion engines. An active dynamometer which is able to test internal combustion engines of up to 100 kW capacity is available at the laboratory. The dynamometers maximum brake torque is 260 Nm at 4000 rpm. The laboratory also contains auxiliary equipment necessary for an internal engine to operate including a fuel delivery and consumption unit, a cooling circuit, an exhaust system, air ventilation unit and fire extinguishing equipment. The diagnostic devices used in the laboratory include torque and speed measurement devices as well as an indicator system capable of measuring in cylinder and intake/exhaust line pressure at 0.5 crank angle degree intervals. The laboratory is frequently used for graduation projects for the automotive engineering MS degree students and also for demonstration experiments of undergraduate courses. A diesel and a gasoline engine are available for testing in the laboratory.

Supervisor: Hasan Bedir, Location: New Hall Basement

|

|

Automotive Acoustics and Vibration Laboratory

|

|

Vibration and acoustics and various related topics such as fatigue and passenger

comfort are among the most important subjects in Automotive Engineering. The laboratory

is founded to examine and solve all kinds of vibration and acoustics problems encountered

in automobiles. The necessary equipment to conduct the experimental studies have

been obtained and carried out in various ongoing projects in the framework of university-industry

cooperation. Currently, in the laboratory besides the experimental equipment such

as a variety of accelerometers, microphones, tachometers, data acquisition systems,

there are a sedan and a body-in-white which investigations are carried out on .

In conjunction with these equipment, components used for educational purposes such

as many and varied features engines, gear boxes, steering systems, such as parts

are also available. Various software and hardware related to dynamics and control

of vehicles are used in the same laboratory. The development studies of alternative

fuel vehicles participated in various competitions on behalf of our university are

also carried out largely in this laboratory.

Supervisor: Günay Anlaş, Location: New Hall

|

|

Composites Laboratory

|

|

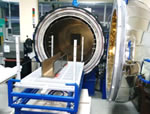

In Composites Laboratory, research on fibre reinforced composites, reinforced plastics and nanocomposites as well as their production methods is being conducted. Composite parts can be produced using several manufacturing methods such as vacuum infusion, autoclave, hot press, induction or microwave heating. Production of novel composites and nanocomposites as well as novel, energy efficient production methods, prediction of manufacturing deformations in composite parts, micromechanical analysis of composite parts, prediction of damage by using various failure criteria, deformation and failure analysis of composite structures, design and optimization of wind turbine blades are among the research topics of interest.

Supervisor: Nuri Ersoy, Location: KB Basement

lab page

|

|

Computational Combustion and Heat Transfer

Laboratory

|

|

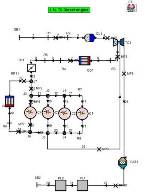

Theoretical modeling and simulation of flame and heat transfer processes are the subjects studied in this laboratory. The reduction of chemical kinetics of hydrocarbon combustion, modeling of turbulent flames, gas phase radiative heat transfer in flames, prediction of emissions from internal combustion engines are the topics currently studied in the laboratory. The laboratory has relevant software packages and computers to allow for the study of the topics mentioned. Available software includes ANSYS FLUENT, AVL FIRE, AVL BOOST, RICARDO WAVE, KIVA, Fortran Compiler, and Matlab.

Supervisor: Hasan Bedir, Location: KB217

|

|

Control

and Dynamics Laboratory

|

|

Research topics are,

- Modeling of Dynamic Systems

- System Identification

- Multivariable and Robust Control

- Vibration Analysis and Balancing

Supervisor: Eşref Eşkinat, Location: KB221

|

|

Design Laboratory

|

|

This lab is used for design and production of senior projects. A variety of machine elements (gears, nuts and bolts, etc.), electromechanical components (electric motors, electromechanical valves, etc.) and electrical and mechanical measuring equipments are available in the laboratory. Several benches are available for the students use as this lab is mostly used for the assembly and test processes.

Supervisor: Çetin Yılmaz and Hakan Ertürk, Location: KB219

|

|

Experimental Engineering Laboratory

|

|

Laboratory training associated with junior level fundamental mechanical engineering courses are combined into a sequence of two courses: Experimental Engineering I and Experimental Engineering II. Laboratory work is conducted in the Experimental Engineering Laboratory of the department. The laboratory is designed to teach hands-on experimental skills and is equipped with equipment for teaching the fundamentals of measurement and instrumentation with emphasis on sensors and transducers. Test setups related to the disciplines of solid mechanics, thermodynamics, heat transfer and fluid mechanics provide the opportunity of conducting experiments in those fields.

Utilization of the laboratory is, in the average, twenty-five hours per week. The laboratory is capable of accommodating seventy-two students per academic term.

The Experimental Engineering laboratory of the department has been approved in both of the ABET accreditation processes.

Supervisor: Evren Samur, Location: KB245

|

|

Flow

Modelling and Simulation Laboratory

|

|

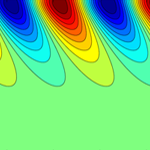

In FMS Laboratory, computational modeling techniques are being developed and applied

to study engineering problems that cover a wide range of application areas such

as Fluid Mechanics, Aerodynamics, Gas Dynamics, Transonic Flow, Non-Newtonian Fluids,

Turbulence, Acoustics, Solidification, Combustion, Chemical Vapor Deposition, Two-Phase

Flow, and other areas of Computational Science, such as Semi-Conductor Device Simulations.

Supervisor: Ali Ecder, Location: M4220

|

|

Haptics & Robotics Laboratory

|

|

Haptics technology is used to generate the sense of touch (i.e., haptics). It allows us to touch and manipulate objects either within a virtual environment or in a real world through teleoperated systems, such as for surgical robots. Research on the haptics technology brought it into computer games, mobile phones, surgical simulators, medical robotics etc. Our lab contributes to this technology by developing smart mechatronic and robotic systems for medicine and human-machine interaction. Our current research focuses on:

- Medical Robotics & Tools

- Sensory Feedback for Robotic Prostheses

- Haptics Technology for Touch Screens

- Assistive Devices for Visually Impaired

Haptics & Robotics (H&R) lab is located in KB112 in North Campus of Boğaziçi University.

Supervisor: Evren Samur, Location: KB112

|

|

High Temperature Materials Laboratory

|

|

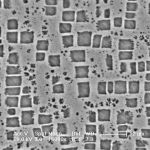

Physical and mechanical metallurgy of high temperature materials, specifically the superalloys, are investigated in this laboratory. Although current emphasis is on the nano-size precipitate evolution in the Ni-base superalloys, microstructure formation via solid-solid or melt-solid transformations, mechanical (tensile, creep, fatigue) testing, and microstructure-property relationships of materials are also explored.

Supervisor: Ercan Balıkçı, Location: KB225

|

|

Materials Testing Laboratory

|

|

This lab is mainly designated for tests required in ME212 Materials Science course. The tests that can be performed in this lab are:

1. Metallography

2. Tensile and compression tests

3. Aging heat treatment and Hardness

4. Impact test

5. Corrosion

Supervisor: Ercan Balıkçı, Location: KB

|

|

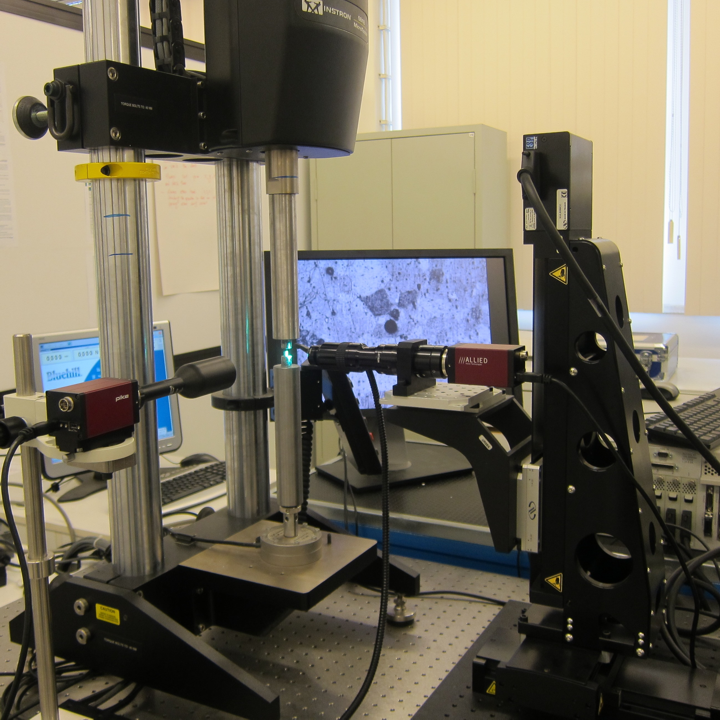

Mechanical Tests Laboratory

|

|

In Mechanical Testing Laboratory, tests on mechanical behavior of polymers, composite materials, ceramics, metals and alloys are performed. Among the tests done in the laboratory are standard tension/compression/flexure tests, fracture mechanics tests and fatigue tests. In addition to these standard tests, special tests can be done on automotive components such as engine mounts, connecting rods, crank shafts according to the company specifications.

MTS and INSTRON servo hydraulic testing machines enable the dynamic tests to be performed, whereas ZWICK Universal Testing Machine enables measurement of elastic properties and static strengths of the materials

Deformation of parts under loading can be measured using strain gages and propagation of fatigue cracks under constant and variable amplitude loading can be monitored by optical and electronic methods. Damages parts can be examined using KRAUTKRAMER ultrasonic testing system.

Supervisor: Nuri Ersoy, Location: New Hall

|

|

Mechanics of Advanced Materials Laboratory

|

|

This lab specializes on in situ full-field deformation measurement at multiple length-scales. Deformation fields can be mapped with intra-grain resolution over an arbitrarily large area through in house scanning equipment. This provides high resolution and high statistical significance (that normally do not coexist) at the same time. The focus of research is on materials with complicated or multi-physics-coupled constitutive behavior (e.g. coupled thermal-mechanical behavior) and deformation-induced transformation phenomena. Studied topics include deformation physics of hexagonal close packed metals that undergo twin transformation and superelasticity in shape memory alloys that is based on an austenite-to-martensite phase transformation. Multiscale measurement is complemented with multiscale modeling activity that includes polycrystalline averaging techniques and various applications of the finite element method.

Supervisor: Günay Anlaş and C. Can Aydıner, Location: KB222

|

|

Solidification and Single Crystal Growth Laboratory

|

|

Research projects in this laboratory investigate solidification behavior of materials. Effects of process variables like the thermal gradient, convection in the melt, and diffusion at the solid-liquid interface are studied to understand the solute redistribution during solidification. This understanding specifically helps identify the underlying phenomena determining the interface stability, which is crucial in the growth of single crystals. The use of single crystals is essential in many industrial fields such as the electronics industry using single crystal semiconductors to increase the conduction efficiency and the aero-space industry employing single crystal superalloys in jet engines to combat the creep at high temperatures.

Supervisor: Ercan Balıkçı, Location: KB224

|

|

Space Technologies Laboratory

|

|

Research projects in Space Technologies Laboratory focuses on the development, analysis and testing of plasma thrusters and components for space propulsion applications as well as the study of various terrestrial plasma applications and devices. Satellites and spacecraft moving in an orbit or in interplanetary space use propulsion systems that use the principle of conservation of momentum to provide thrust. Various propulsion concepts that will use external energy sources received from on-board batteries, solar panels, nuclear reactors, etc. are being developed and studied in this laboratory.

Supervisor: Murat Çelik, Location: KB Basement

|

|

Thermal and Energy Systems Laboratory (TESLa)

|

|

TESLab is located in KB-215 (in North Campus) and its goal is to develop methods and tools for design, measurement and control of thermal and energy systems. Our research focuses on several applications

- Design and production of improved materials for renewable energy and improved thermal transport relying on nano-technology

- Multi-scale modeling and characterization of nano-scale thermal transport.

- Design and control thermal systems

- Thermal management and testing of opto-electronic packages

We are not only focused on contributing to the scientific literature in these areas, but also provide solutions to practical problems using numerical and experimental techniques. Due to the multi-scale nature of these problems, we focus both on microscopic and macroscopic modeling and characterization methods. Moreover, we use novel design and characterization approaches for some of these applications such as inverse design or regularization based tomography techniques.

Supervisor: Hakan Ertürk, Location: KB215

|

|

Vibrations Laboratory

|

|

Vibrations Laboratory is equipped with the instrumentation and software required for measurement and analysis of vibrations of structures and machinery. In the lab, there are two shakers for low frequency high force and high frequency low force applications, data acquisition systems, accelerometers, a laser vibrometer, an oscilloscope, and other miscellaneous electrical and mechanical measurement instruments.

Current research in the lab focuses on computational and experimental investigation of vibration isolation systems, passive and adaptive vibration absorber systems, and phononic band gap structures.

Supervisor: Çetin Yılmaz, Location: KB216

|

|